Making Best Use Of Effectiveness: Picking the Right Aftermarket Construction Parts for Your Fleet

Making Best Use Of Effectiveness: Picking the Right Aftermarket Construction Parts for Your Fleet

Blog Article

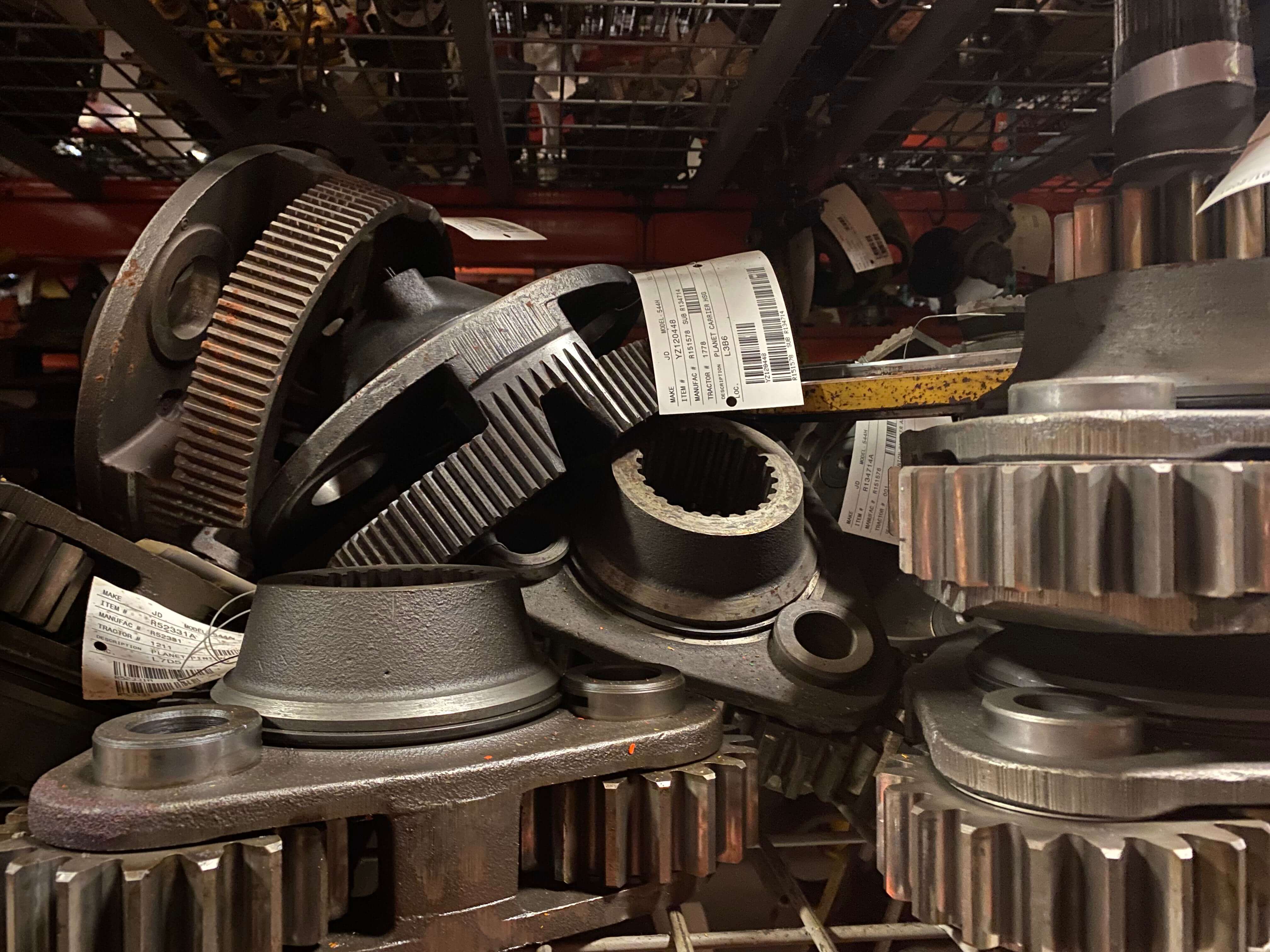

Increase Efficiency With Aftermarket Components: a Guide for Heavy Machinery Owners

Advantages of Aftermarket Components

Owners of heavy machinery can enjoy many benefits by opting for aftermarket parts over initial devices maker (OEM) parts. Aftermarket components are typically extra economical than OEM components, allowing equipment owners to reduce maintenance and repair expenses without jeopardizing on high quality.

An additional advantage of aftermarket parts is the bigger option available on the market. Since aftermarket suppliers focus on producing details elements, machinery proprietors have access to a broader array of options to match their requirements. This variety can bring about enhanced efficiency and effectiveness of the equipment. In addition, aftermarket parts are recognized for their high quality and integrity, with numerous conference or exceeding OEM criteria.

Finally, picking aftermarket parts can also lead to faster fixings and reduced downtime. With much easier schedule and quick delivery options, machinery owners can get their devices up and running once more promptly, minimizing interruptions to their operations.

Selecting the Right Aftermarket Components

When considering aftermarket parts for heavy machinery, it is necessary to focus on compatibility and top quality to make certain optimal performance and longevity of the equipment. Selecting the best aftermarket parts can be an important choice for hefty equipment proprietors as it straight affects the performance and integrity of their tools.

Second of all, high quality needs to never ever be endangered when picking aftermarket parts (aftermarket construction parts). Going with premium components makes certain sturdiness, reliability, and general performance of the machinery. It is advisable to source aftermarket components from reputable suppliers or distributors known for their high quality standards

Furthermore, taking into consideration aspects such as guarantees, customer testimonials, and compatibility with existing systems can additionally aid in making the best choice. By focusing on compatibility and high quality when selecting aftermarket components, hefty machinery proprietors can improve the efficiency and long life of their devices.

Installation and Upkeep Tips

For effective procedure and durability of hefty machinery, correct installation and normal maintenance are vital. When installing aftermarket components, ensure that you very carefully follow the maker's instructions to assure optimal efficiency. It is important to utilize click here to find out more the correct tools and strategies to stop any type of damages during the installment process. Routine maintenance is crucial to keep your equipment running efficiently. Develop a maintenance routine that consists of tasks such as checking fluid degrees, evaluating for wear and tear, and cleaning elements (aftermarket construction parts). Without delay address any type of problems that emerge to stop additional damage and expensive repair services. In addition, consider purchasing training for your maintenance personnel to ensure they have the needed abilities to recognize and resolve potential problems. By prioritizing installation and maintenance procedures, you can make best use of the performance and lifespan of your hefty equipment, inevitably conserving time and cash in the lengthy run.

Cost-Effectiveness of Aftermarket Components

Correct setup and routine maintenance are fundamental elements for heavy equipment proprietors aiming to assess the cost-effectiveness of aftermarket components for their devices. While original tools maker (OEM) parts are recognized for their high quality, aftermarket parts supply an even more economical solution without endangering performance. The cost-effectiveness of aftermarket parts ends up being apparent in numerous methods. read this article Aftermarket components are typically a lot more economical ahead of time, enabling proprietors to achieve financial savings on initial acquisition prices. Furthermore, these components frequently give comparable efficiency to OEM components, guaranteeing that the equipment runs effectively without the demand for expensive replacements. In addition, the availability of aftermarket parts from a large range of vendors promotes competitors, bring about competitive prices and more price savings for owners. By carefully assessing the high quality and compatibility of aftermarket components with their equipment, proprietors can strike an equilibrium in between cost-effectiveness and performance, ultimately making best use of the efficiency and longevity of their heavy equipment.

Optimizing Performance With Aftermarket Upgrades

To boost functional efficiency and performance, heavy machinery owners can properly take full advantage of performance with tactical use of aftermarket upgrades. Aftermarket upgrades use the opportunity to customize hefty machinery to details operational needs, causing improved functionality and outcome. website here Upgrading parts such as engines, transmissions, hydraulic systems, and tracks can substantially enhance the total effectiveness of the machinery.

Regularly assessing the efficiency of hefty machinery and determining locations where aftermarket upgrades can be valuable is essential for making best use of effectiveness. By spending in top quality aftermarket components and upgrades, equipment owners can attain greater degrees of performance, ultimately resulting in cost financial savings and boosted operational outcomes.

Final Thought

In verdict, aftermarket components provide numerous advantages for heavy machinery owners, consisting of cost-effectiveness, enhanced efficiency, and modification alternatives. By choosing the ideal aftermarket parts, adhering to proper installation and maintenance procedures, and making best use of upgrades, heavy machinery proprietors can boost their equipment's performance and durability. Buying aftermarket parts can inevitably result in boosted productivity and decreased downtime, making it a rewarding factor to consider for proprietors wanting to optimize their machinery operations.

Proprietors of heavy equipment can enjoy numerous advantages by choosing for aftermarket components over initial equipment supplier (OEM) parts. Aftermarket parts are usually much more inexpensive than OEM components, enabling machinery proprietors to decrease upkeep and fixing costs without compromising on top quality. By carefully reviewing the quality and compatibility of aftermarket parts with their machinery, proprietors can strike an equilibrium in between cost-effectiveness and performance, eventually taking full advantage of the performance and longevity of their heavy tools.

In final thought, aftermarket parts use countless benefits for heavy equipment proprietors, including cost-effectiveness, increased performance, and personalization alternatives. By picking the ideal aftermarket components, adhering to proper installment and maintenance treatments, and optimizing upgrades, heavy equipment owners can improve their equipment's performance and long life.

Report this page